Does Adding Sodium Sulfate Filler to PE and Composite Films Really Reduce Costs?

Some film blowing manufacturers aggressively add sodium sulfate (Na₂SO₄)-priced at just 3,000 RMB/ton-as filler to cut costs. While adding 15% sodium sulfate reduces material cost by 27%, and 20% delivers savings of 36%, the apparent per-kg price drop actually increases end-user costs.

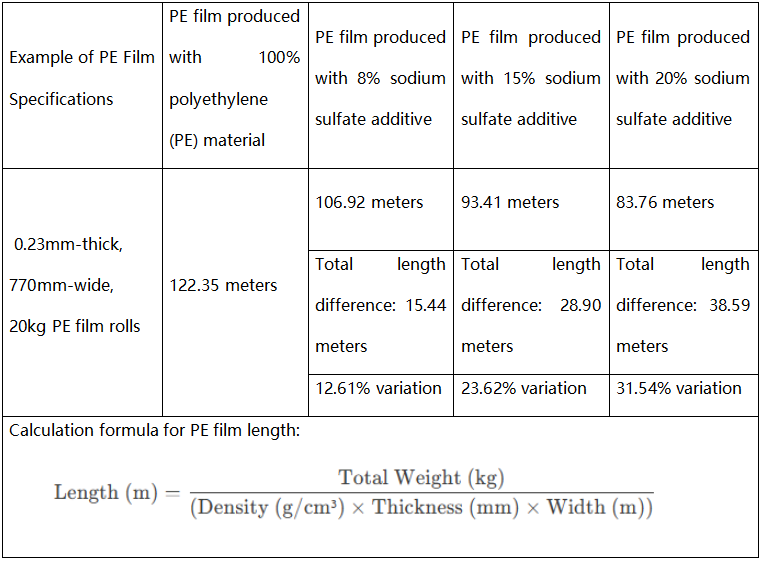

With a density of 2.2-2.5g/cm³ (vs. PE's 0.923g/cm³), higher sodium sulfate content drastically reduces PE film meterage:

15% filler →23.62% shorter PE film

20% filler →31.54% shorter PE film

Though sold at lower prices per kg, these filler-added films deliver substantially less usable material than pure PE films. We recommend PCB manufacturers implement meterage verification during PE film inspection.

Comparative Calculation:

For 0.23mm-thick, 770mm-wide, 20kg PE film rolls:

Hidden Risks of Adding Sodium Sulfate to PE Films:

Many consumers overlook the precipitation risks associated with sodium sulfate-blended PE films. Under high humidity or prolonged storage, the sodium sulfate within the film migrates and precipitates to the surface, leading to weakened composite strength and bag failures. We recommend that clients include post-use bag breakage and air leakage in their quality anomaly monitoring.

For circuit board packaging, these precipitates adhere to precision components, creating potential malfunction risks. In food and pharmaceutical packaging applications, given sodium sulfate's high water solubility, the critical question remains: are the potential health impacts from human ingestion truly acceptable?

How to Identify Sodium Sulfate-Blended PE Films?

1. Visual Inspection:

Films with sodium sulfate exhibit rough, whitish surfaces, poor transparency/gloss, and stiff texture.

Pure PE films feature high transparency, smooth surfaces, and soft texture.

2. Meterage Verification:

Compare actual film length against reference values shown in the accompanying chart.

Sodium sulfate-blended PE and composite films not only significantly reduce usable meterage (increasing material costs) but also introduce quality inconsistencies and precipitation risks.

We strongly recommend purchasing 100% polyethylene-based PE and composite films.